How our bottle refill system works

- Choose which wine you want from our list;

- Drink in and choose a small, medium or large glass (or carafe of wine) – prices are very reasonable at £5.50 for a small (125ml), £7.50 for a medium (175ml), £11 for a large glass (250ml) or £22 for a carafe (500ml);

- Wines we have on at the moment are: NZ Sauvignon Blanc and Argentine Malbec;

- Or takeaway – we supply a 750ml bottle for £3 and fill it up; or you bring your own! You can also bring your own 1-litre bottle to fill up (or 2-litre bottle – we have filled one up).

The benefits of our wine refill system

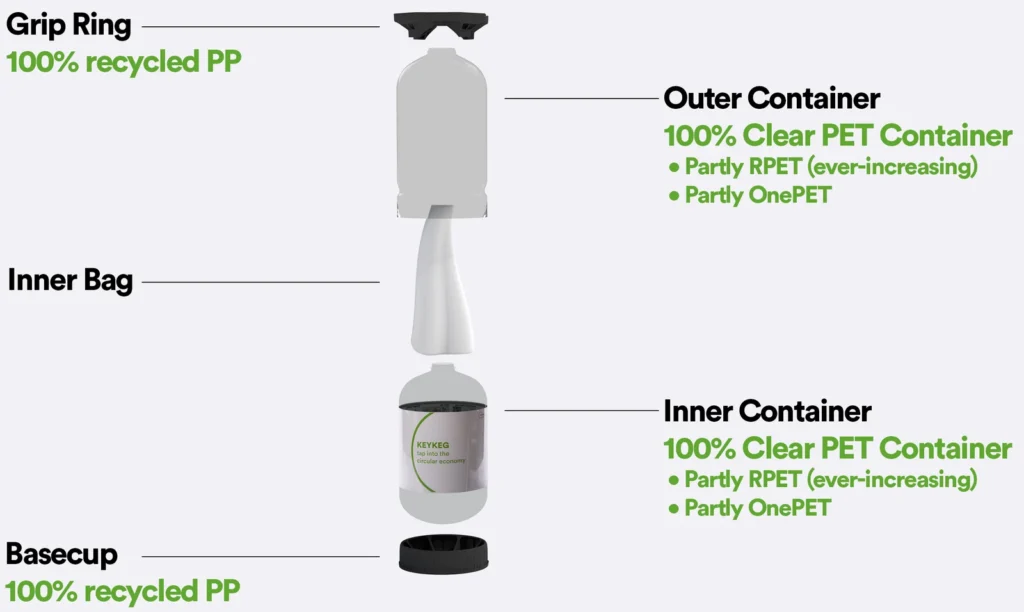

Recycled polyethylene tetraphyte (rPET) must be ‘food grade’ quality for KeyKeg’s transparent walls, but circular-quality rPET is not always possible. Therefore, the amount of rPET Key Keg as a company uses fluctuates, but on average there is about 50% circular material in each new KeyKeg.

KeyKeg is compliant with ISO 18604, the international standard for packaging-material recycling and the environment. While 86% of every empty KeyKeg is suitable for recycling, KeyKegs are designed to be circular rather than recyclable Kegs.

Due to their light weight, it’s possible to transport 35% more beverage per truckload using these sustainable kegs instead of using steel kegs. More beverage in each load means fewer shipments, or a transport-cost saving of up to 65%.

One 20 litre KeyKeg replaces 27 bottles of wine. More wine can be transported per pallet and per container with these lightweight kegs.

Each year, 25 million tonnes of plastic is produced in Europe, of which only 30% is recycled. 39% is incinerated and 31% is used for landfill (EU, 2018). The KeyKeg reuse goal sees all empty KeyKegs used as circular materials for new kegs instead of letting them be incinerated or used as landfill.

It’s estimated that cleaning a returned steel keg with harsh cleaning chemicals uses 8-20 litres of hot water.

- 27 bottles of wine are replaced by one 20l Key Keg

- 16kg less glass

- 1.6kg less cardboard

- 50% reduction in bottled wine’s storage footprint